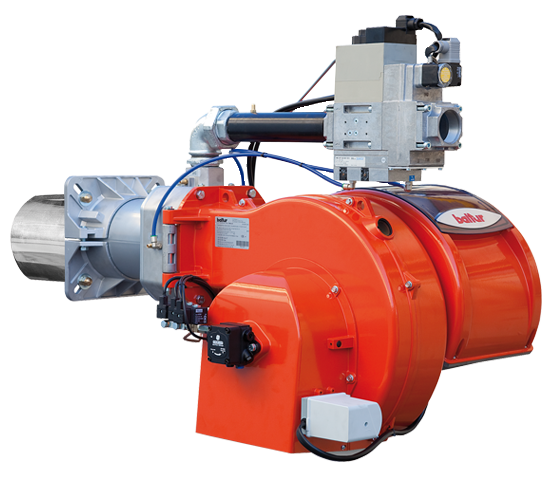

TBML 310 LX ME 60Hz

Code 56895410Progressive/modulating two-stage gas/light oil dual fuel burners with electronic cam

- Electronic modulation.

- Mechanical pulverization.

- Alternative operation.

- Home

- Products

- Burners

- Dual Fuel Gas Light Oil

- TBML 310 LX ME 60Hz

Technical data

Fuel

Natural Gas

Operation

Electronic Modulation

Minimum Thermal Power (kW) to ErP

500

Maximum Thermal Power (kW) to ErP

3200

Min flow rate (Sm³/H)

53

Max flow rate (Sm³/H)

339

Second Fuel

Light oil

Second Fuel Operation

Two-stage

Second Fuel Min Thermal Power (kW)

950

Second Fuel Max Thermal Power (kW)

3200

Min flow rate (kg/h)

80

Max flow rate (kg/h)

270

Max Viscosity (°E)

1.5

Electric power supply type

AC

No. of Phases

3N

Power Supply Voltage (V)

380

Power Supply Frequency (Hz)

60

Fan Motor Power (kW)

9

Weight with packaging (kg)

160

Width (mm)

1070

Depth (mm)

1070

Height (mm)

810

Technical Descriptions

Burner with alternate methane gas/diesel fuel supply, EC approved according to European Directives EN676 and EN267. Gas side modulating operation, diesel side two-stage

Modulation ratio 1:6

Gas burner with low NOx and CO emissions in accordance with European standard EN676: class 3

Burner with Low NOx and CO emissions on light oil according to European standard EN267: 2

Combustion air intake with throttle damper. Air flow adjustment with electric servomotor

Combustion head adjustment

Fully closing air damper on shutdown to avoid loss of heat through the chimney.

Maintenance facilitated by the possibility of removing the combustion head without having to remove the burner from the boiler.

Sliding boiler coupling flange to adapt the blast-pipe to the various types of boilers

Easy maintenance thanks to the two-sides hinge which allows the removal of the combustion head without having to remove the burner from the boiler.

Device made of sound-absorbing material to reduce fan noise

CE version gas train is complete with butterfly valve, operation and safety valve with electromagnetic drive, valve tightness control, minimum pressure switch, pressure regulator and gas filter

Fail proof connectors for burner/gas train connection

Gas train exit: up

Pump connected to fan motor through electromagnetic clutch

Fuel supply circuit made of gear pump with pressure adjustment, shut-off valves and safety valve

Manual fuel switching

Flame detection by means of infrared IRD photocell

Control panel equipped either with display showing the working process and with the keyboard for the burner adjustment.

Electrical system with protection rating IP40

Operating range

This product is part of the range TBML LX ME

Discover the entire seriesLogin

Burners

Burners

Websolute

Websolute